Have you ever wondered how to make an air purifier last longer? The answer lies in a small device - a cooling fan. After applying the cooling fan to the air purifier, it can bring many benefits and give your air purifier a new life.

First, cooling fans improve ventilation efficiency. A good ventilation system is essential for an air purifier. Cooling fans introduce fresh air and discharge the treated air, helping the air purifier to better circulate air and improve purification efficiency. By improving ventilation, the cooling fan reduces the burden on the filter screen and prevents pollutants from accumulating inside the purifier, thereby extending the service life of the filter screen.

Secondly, the cooling fan can avoid the failure caused by overheating. Overheating may cause damage or failure of key components of the air purifier, affecting the stability and life of the product. By applying cooling fans, key components can be cooled effectively, reducing the risk of failure caused by overheating and making your air purifier more reliable.

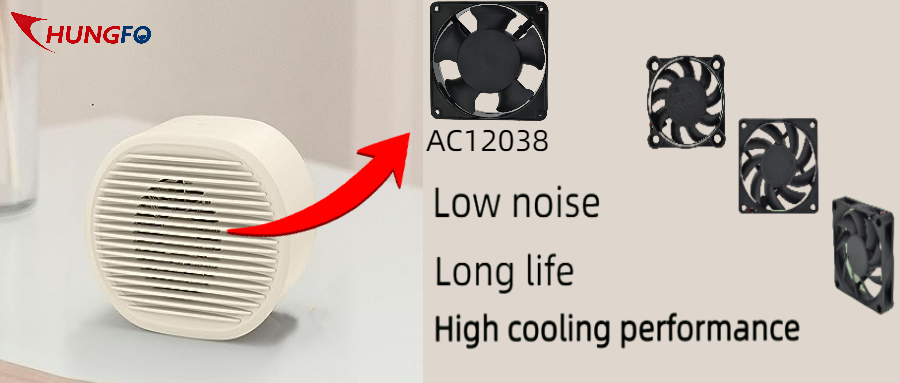

Finally, cooling fans improve stability. Overheating can cause instability in the performance of the air purifier, such as noise, downtime and other problems. The use of cooling fans can keep the air purifier running at a suitable working temperature, maintain its stability, and improve the reliability and service life of the product. Like our Chungfo also has an application in the air purifier axial flow heat fan, AC12038, ultra-long life cooling fan. The fans can work very quietly, and the minimal noise ventilation system enables axial flow fans to have higher airflow for enhanced cooling performance. The PBT housing and blade ensure operation in the operating temperature range from -10 ° C to +70 ° C; Large air volume, uniform wind in and out, wear resistance, high temperature resistance; And has passed CE, UL and RoHS certification, is specially tailored for air purifier environmental protection equipment cooling fan! Guangdong Chungfo Electronic Technology Co., Ltd. is dedicated to the equipment cooling needs of various industries, is a professional cooling fan manufacturer. We can provide professional customization of cooling fans according to customer needs. If you have this need, please feel free to contact us.