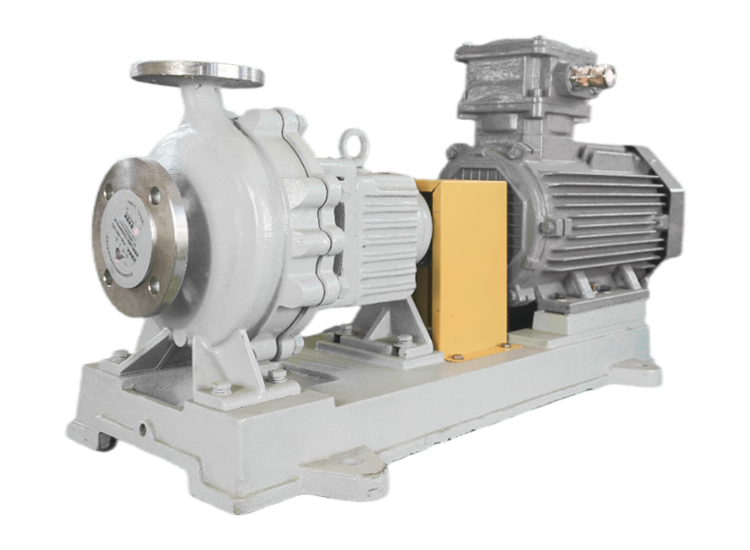

THJ Chemical Process Centrifugal Pump: Key Role in Evaporation Systems

I. Main Tasks of Pumps in Evaporation Systems

1. Material Transfer: The THJ centrifugal pump is crucial in evaporation and crystallization setups. It moves feedstock, intermediate products, condensate, and concentrated liquids between containers or pushes fluids through heaters and heat exchangers.

2. Circulation & Mixing: In some crystallization methods, the THJ pump keeps the solution circulating. This helps distribute heat evenly, stops hot spots, and ensures even crystal growth.

3. Flow & Pressure Control: By changing speed or valve settings, the THJ pump controls flow rates into evaporators and manages pressure in the system. This is key for consistent evaporation and crystallization.

4. Flow Rate & Head: It’s important to accurately figure out the flow and head needed for the system to avoid inefficient pump operation, which saves energy.

5. Corrosion Resistance & Materials: Since these pumps face acids, bases, and salts, they need to be made from tough materials like stainless steel, titanium, alloy steel, or have protective coatings.

6. Temperature & Pressure Tolerance: Pumps should handle high temperatures and pressures for reliable performance during intense crystallization.

7. Wear Resistance: With solid particles present, pumps need durable designs, like open impellers or special liners, to reduce wear.

8. Self-Priming & Cavitation Resistance: For jobs with frequent starts and stops or cavitation risks, pumps should be able to self-prime easily.

9. Sealing Systems: Double-face cartridge mechanical seals are best for handling abrasive materials while ensuring durability and staying eco-friendly.

10. Maintenance & Cleanability: Pumps that deal with crystallizing fluids should be easy to take apart for maintenance and cleaning.

11. Energy Efficiency: High-efficiency THJ pumps that meet industry standards can lower operating costs and fit well with eco-friendly practices.

II. Choosing Evaporation-Crystallization Pumps

THJ centrifugal pumps work differently from standard designs by using impeller thrust instead of just centrifugal force to move fluids:

1. Fluid Intake: The motor turns, creating a vacuum that pulls liquid into the pump.

2. Energy Transfer: Helical impeller blades create thrust, adding kinetic and pressure energy to the fluid.

3. Discharge: The fluid speeds up as it exits the pump, and the vacuum keeps the process going. This approach is great for high-flow, low-head tasks.

III. Industrial Uses

THJ pumps are common in evaporation, crystallization, and chemical processes across various industries:

1. Phosphate Fertilizers: Used in phosphoric acid and ammonium phosphate production.

2. Bayer Process Alumina: Circulates aluminum sodium solutions in evaporators.

3. Chlor-Alkali: Handles evaporation of caustic soda with salt.

4. Vacuum Salt Production: Circulates liquid in salt crystallizers.

5. Sodium Sulfate Plants: Manages Na₂SO₄ evaporation tasks.

6. Hydrometallurgy: Used in copper and nickel sulfate crystallization.

7. Alkali Refining: Works with NH₄Cl crystallizers.

8. Soda Ash: Recovers CaCl₂ in evaporators.

9. Pulp & Paper: Concentrates black liquor.

10. Power Plants: Involved in Flue Gas Desulfurization systems and ammonium sulfate crystallizers.

11. Light Industry: Used in alcohol, citric acid, and sugar evaporation.