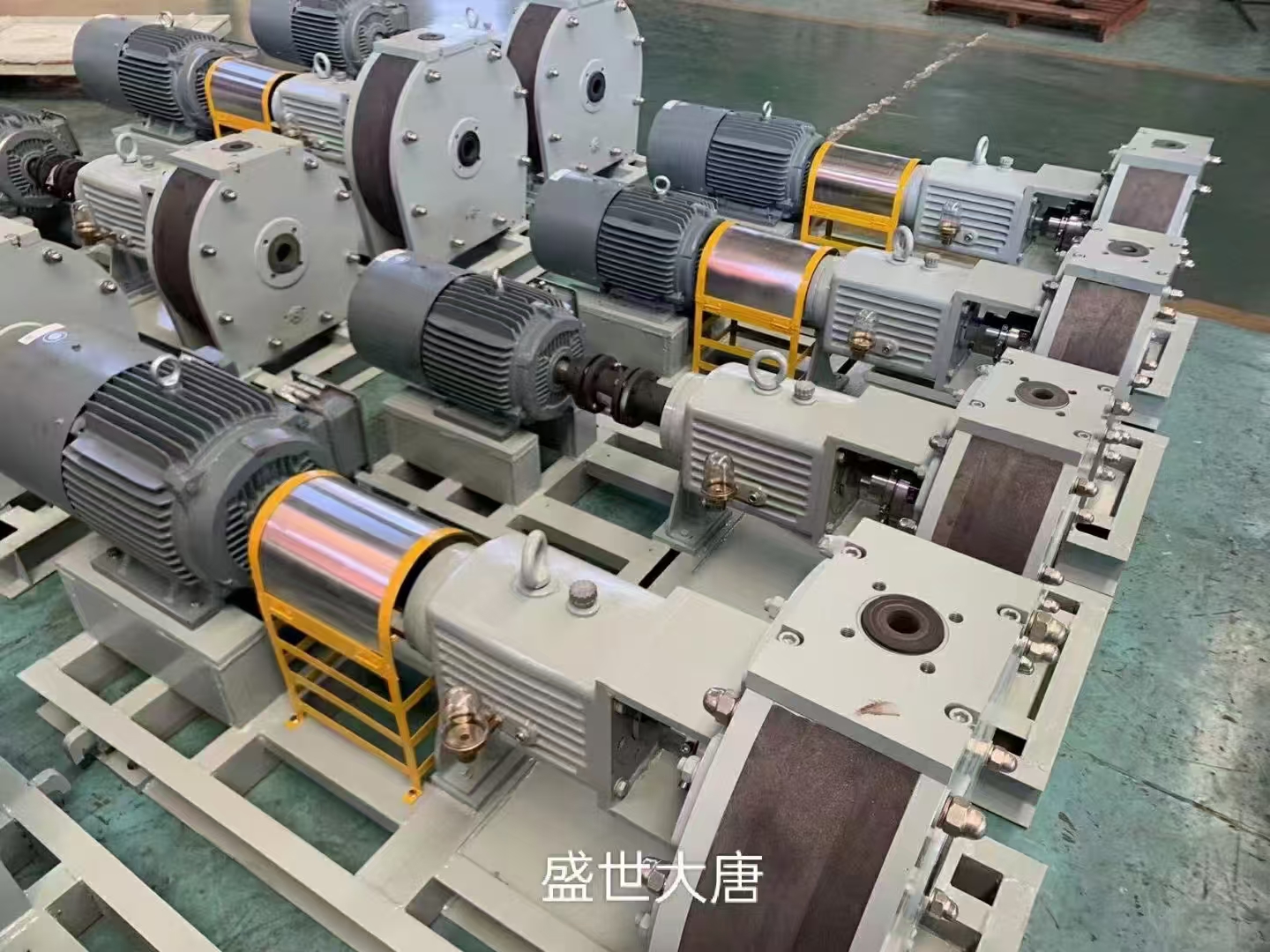

Shengshi Datang Group is an integrated industrial and trading company specializing in the production and sales of magnetic pumps and centrifugal pumps. These two types of pumps have distinct characteristics.

Magnetic pumps are suitable for hazardous media such as flammable, explosive, or toxic gases. Their advantages include safety, environmental friendliness, and leak-free operation. However, they also have drawbacks: they cannot transport liquids containing solids or particles, as the internal rotor may become clogged, and the diversion holes may fail to achieve optimal cooling and lubrication, potentially leading to overheating failures. Additionally, if the specific gravity of the medium exceeds 1.5, I do not recommend using magnetic pumps, as their magnetic coupling may slip, making it difficult to discharge the liquid.

Centrifugal pumps, on the other hand, are cost-effective and capable of handling high-specific-gravity substances. However, their mechanical seals have limited effectiveness and are prone to leakage over time, which can pollute the environment. Moreover, they can only handle liquids with particle or crystal content below 5%. If the content is up to 8%, it is advisable to use them in conjunction with double-flushed mechanical seals.