Want to know what makes an air-cooled refrigerator special? Don't worry, today we're going to focus on a component that can't be ignored: the cooling fan. In fact, cooling fans play a crucial role in air-cooled refrigerators, and they have some compelling special designs and features, so let's take a look.

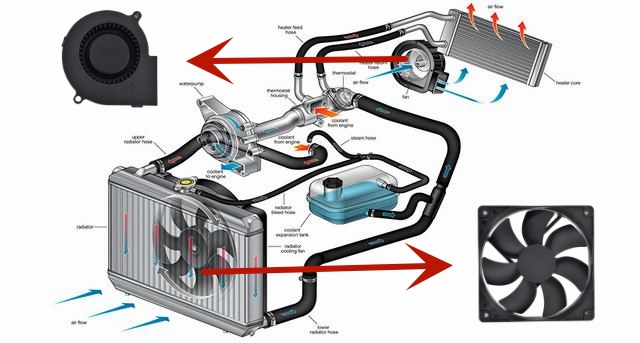

First of all, the location of the cooling fan deserves attention. They are usually located on the back of the refrigerator and are closely connected to the condenser. The choice of this location is not accidental, as it is able to effectively expel the generated heat, ensuring that the inside of the refrigerator maintains the proper temperature. This design improves the cooling effect while avoiding problems caused by overheating.

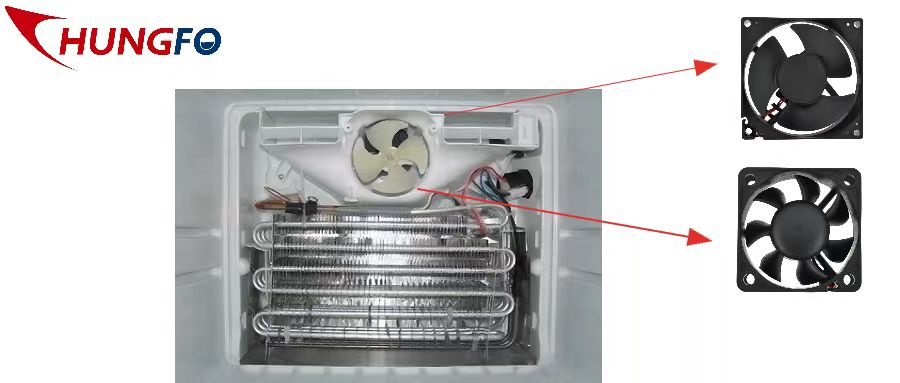

Secondly, the design and materials used in the cooling fan are also very special. They usually consist of efficient fan blades and a main air lead. Just like Chungfo's design and production of blades capable of low noise output high air volume, these fan blades are specifically designed to produce a strong airflow to provide sufficient cooling effect. The selection of materials takes into account the impact of long-term operation and low temperature environment on the fan, so that it can work in difficult conditions for more than five years without trouble.

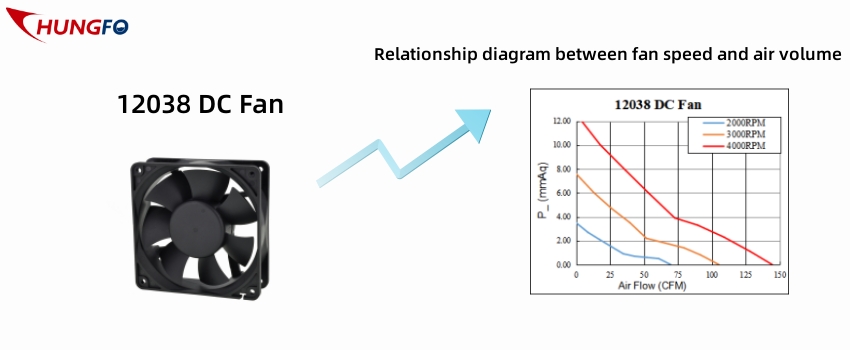

Finally, the cooling fan also has intelligent control and adjustable functions. Some modern air coolers are equipped with intelligent control systems that can automatically adjust according to the temperature and load in the refrigerator. This means that the cooling fan can automatically start and stop as needed to work more efficiently. This feature helps to save energy and extend the life of the fan. The PCB board of the cooling fan produced by us is almost assembled by a professional technical team of workers, so when the customer requires the fan to have a self-starting function, TC temperature control function, RD alarm signal and so on, we can meet. And our company has many models of cooling fans are used in the refrigerator, such as D09232 this model of DC fan is the classic model of refrigerator application, most of the well-known refrigerator factories will use.

In general, the cooling fan in the air-cooled refrigerator has many special features. From the selection of their location, to the choice of design and materials, to the application of intelligent control and adjustable functions, these fans make an important contribution to the performance and effectiveness of the refrigerator. Guangdong Chungfo Electronic Technology Co., Ltd. is dedicated to the equipment cooling needs of various industries, is a professional cooling fan manufacturer. We can provide professional customization of cooling fans according to customer needs. If you have this need, please feel free to contact us.