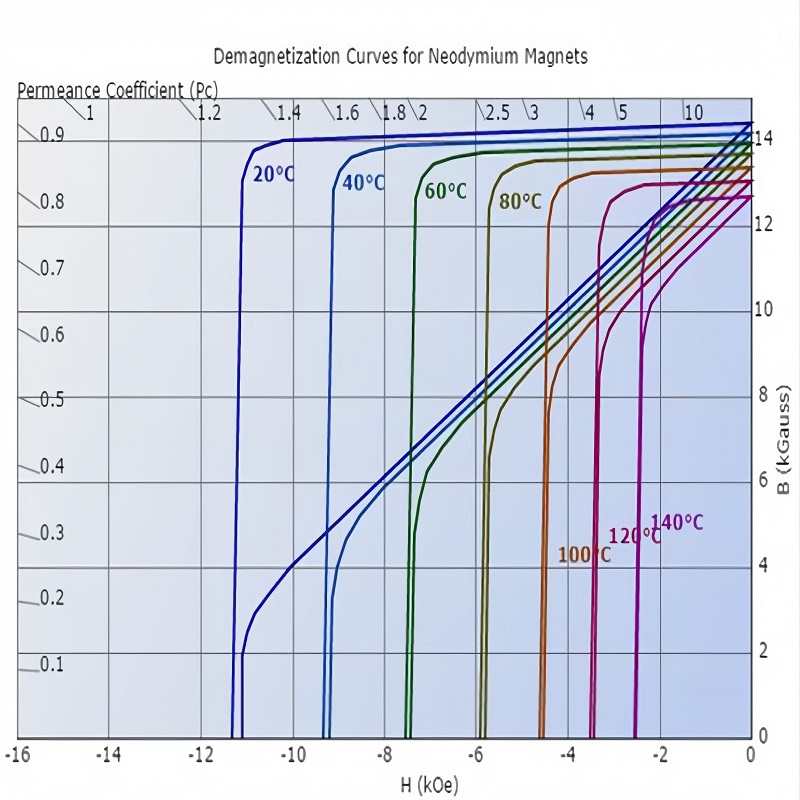

High temperature resistant ndfeb magnets are widely used in various applications due to their powerful magnetic properties. However, their performance tends to degrade at high temperatures, which limits their use in certain environments. The good news is that there are several methods to enhance the high-temperature resistance of these magnets, allowing them to maintain their strength and functionality in extreme conditions.

Material Composition Adjustments

One of the most effective ways to improve the high-temperature stability of neodymium magnets is by modifying their material composition. By introducing specific elements into the alloy, such as dysprosium (Dy) or terbium (Tb), the magnets can be made more resistant to heat. Dysprosium, in particular, helps to improve the coercivity (resistance to demagnetization) of neodymium magnets at elevated temperatures. This ensures that the magnet retains its strength even when exposed to extreme heat.

Coatings and Surface Treatments

In addition to altering the material composition, coatings and surface treatments play a crucial role in enhancing the high-temperature performance of durable rare earth magnets. Applying protective coatings can help shield the magnets from oxidation, which is another factor that can degrade their performance at high temperatures. These coatings provide a thermal barrier and help maintain the structural integrity of the magnet, even in harsh environments.

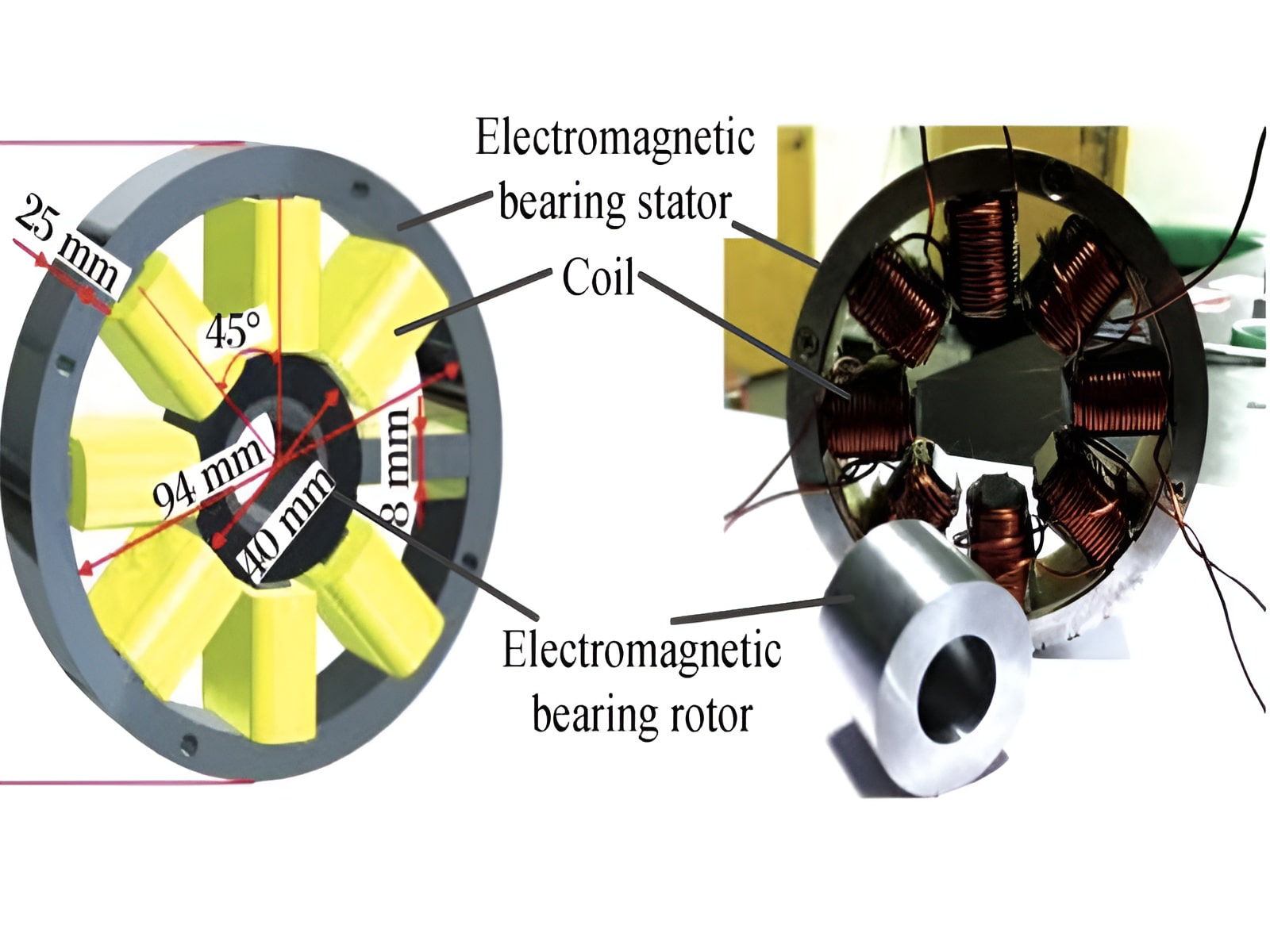

Advanced Magnet Design

Another approach to improving high-temperature performance is through advanced magnet design. For example, incorporating multi-layered coatings or using composite magnet structures can help distribute thermal stress more evenly. This allows the magnets to handle temperature fluctuations better without compromising their magnetic strength.

Conclusion

While neodymium magnets are known for their powerful magnetic properties, their performance at high temperatures can be a challenge. By adjusting their material composition, applying protective coatings, and optimizing their design, it is possible to significantly improve their high-temperature resistance. As technology continues to advance, these innovations will allow good performance neodymium magnets to be used in even more demanding applications, from electric vehicles to aerospace technology, where high temperature stability is critical.

| suffix on a brand name | Rev.Temp.Coef.of Induction(br),a,%/℃(20-100℃) | Rev.Temp.Coef.of Coercivity(Hci),b,%/℃(20-100℃) | Maximum working temperature |

| N | -0.12 | -0.6 | 80℃=176℉ |

| N | -0.12 | -0.58 | 100℃=212℉ |

| H | -0.11 | -0.58 | 120℃=248℉ |

| SH | -0.1 | -0.55 | 150℃=302℉ |

| UH | -0.09 | -0.52 | 180℃=356℉ |

| EH | -0.085 | -0.5 | 200℃=392℉ |

| VH/AH | -0.08 | -0.45 | 230℃=446℉ |

| 60℃ for N50 and N52 |